PPGL DX51D

Category:

PPGL Coil

Key Words:

PPGL Coil

PPGL DX51D

DX51D galvanized sheet material is a non-ferrous alloy mainly composed of zinc as the matrix and other elements. The main alloy elements are aluminum, copper, magnesium, etc. Zinc alloy has low melting point, good fluidity, easy plastic processing and welding, and is resistant to atmospheric corrosion. According to the manufacturing process, it can be divided into cast zinc alloy and deformed zinc alloy. The commonly used cast zinc alloy is zinc aluminum copper magnesium alloy. Its casting process performance is good, and the cooling rate has little impact on the mechanical properties. It is mainly used to manufacture mechanical parts, toys, decorations, household appliances, etc. The commonly used wrought zinc alloys are zinc aluminum alloy and zinc copper alloy. The former contains 4%~15% aluminum. In order to improve the strength and hardness of the alloy, a small amount of copper, magnesium and other alloy elements are added. It has high strength and is easy to form. It can replace some brass or duralumin to make precision forgings. The latter is 0.7%~1.5% copper, which can increase the strength and impact toughness of the alloy and reduce the plasticity. Zinc copper alloy is suitable for making daily hardware products or replacing part of brass.

PPGI is galvanized color plate, PPGL is galvanized color plate, both are color plates, the substrates are different, one is galvanized structure, the other is galvanized structure, the substrate is different, which determines the difference in performance.

Advantages: It not only has the mechanical strength and easy forming properties of steel plates, but also has good decorative properties and corrosion resistance of organic materials. The coating has strong adhesion and can keep the color fresh for a long time. Application: Widely used in various fields such as construction, home appliances, furniture, public facilities and transportation.

|

DX51D PPGI/PPGL |

|

|

Manufacturer JIS DIN high-quality electro-galvanized steel coil |

|

|

Product name: |

DX51D PPGI/PPGL |

|

Place of Origin: |

JChina |

|

Type: |

Steel Coil |

|

Standard: |

AiSi, ASTM, bs, DIN, GB, JIS |

|

Certificate: |

ISO9001 |

|

Grade: |

SPCC,SPCD,SPCE/DC01.DC02.DC03/ST12,Q195 .Etc |

|

Thickness: |

0.1-5.0mm |

|

Surface structure: |

anti-finger print /skin pass/oiled/ dry/chromated |

|

Size: |

Customized according to customer needs |

|

Tolerance: |

±1% |

|

Processing Service: |

Bending, Welding, Decoiling, Cutting, Punching, Welding |

|

Invoicing: |

by actual weight |

|

Delivery Time: |

7-15 days |

|

Technique: |

Hot Rolled Based, Cold Rolled |

|

Port: |

Tianjin Qingdao or according to your requirement |

|

Packaging Details |

in bundles, in bulk, customized packing. |

PACKING AND SHIPPING

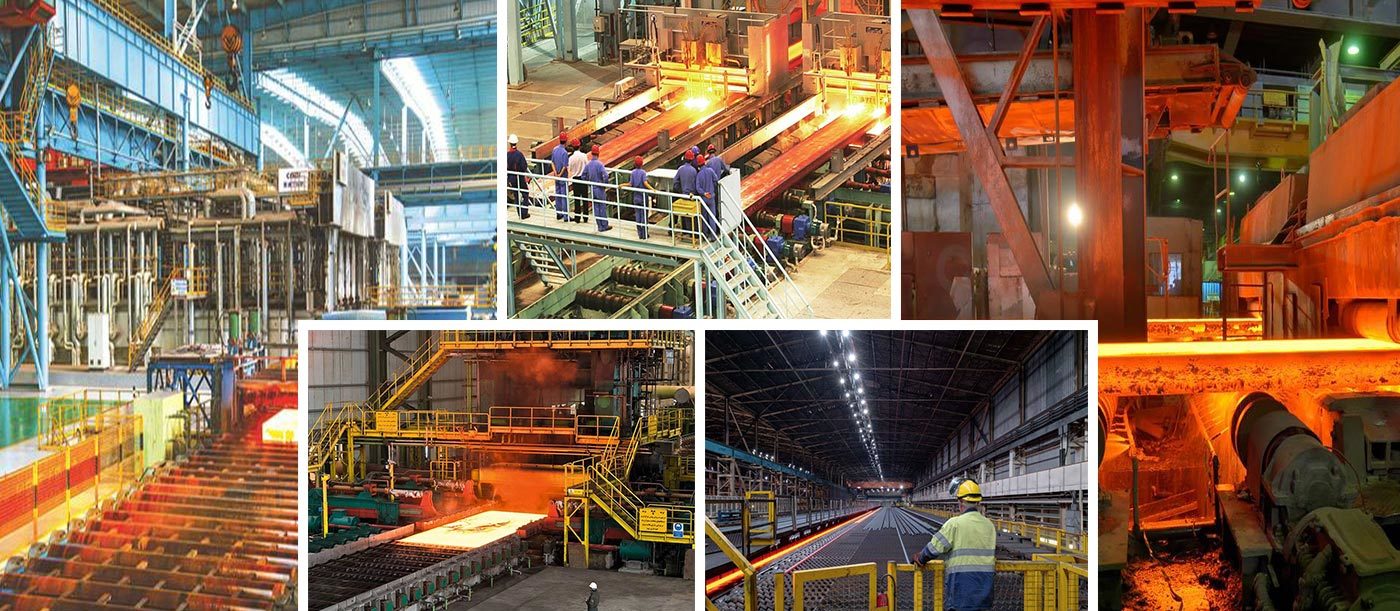

The company has main production lines such as pickling, cold rolling, hot-dip galvanizing, hot-dip galvanizing, thick plate galvanizing, and color coating, forming an annual output of 1 million tons of pickling coils, 1 million tons of cold-rolled steel sheets, and 900,000 tons of hot-dip steel sheets. The scale of galvanized and hot-dip aluminum-zinc-silicon steel sheets, 450,000 tons of thick galvanized steel sheets, and 300,000 tons of color-coated steel sheets. It is one of the largest suppliers of steel and non-ferrous metal smelting and processing in Shandong Province.

FACTORY

Shandong Baopu Metal Products Co., Ltd. was established in March 2010. It is a comprehensive large-scale enterprise integrating coating products and various steel processing and production, warehousing, distribution, and foreign trade sales.

CUSTOMER VISIT

RELATED PRODUCTS